From the advent of the power loom by Edmund Cartwright in 1784 to the development of carbon fibre and more, the UK has always been a pioneer in composite manufacturing.

Here at the AMRC we’re at the forefront of this ever-changing area, relentless in our pursuit of new ways to improve processes, reduce costs and increase sustainability.

With our extraordinary machines and the best engineering minds at your disposal, the only limit is your imagination.

Lighter, cheaper, less wasteful

Composite materials offer a wealth of advantages. Instead of machining what you need from a piece of metal, you can create an item to the specific shape and properties you need in a single process for the intended application. It’s versatile and it means less waste material.

You can create much lighter parts, which can generate cost reductions and efficiencies, particularly in aerospace. A kilo less weight on an aeroplane makes a huge difference, saving 180 kilos of fuel and 600 kilos of carbon dioxide per year.

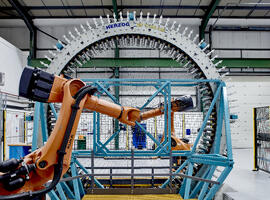

With the help of composite moulding processes, you can produce very complex parts in one go, reducing the need for additional machining and enabling you to streamline your process.

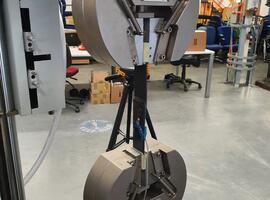

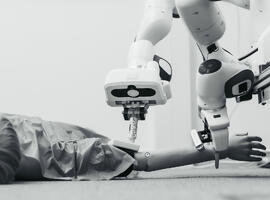

We possess the knowledge and technology for dry fibre composites, whilst retaining our expertise in more traditional processes. And by using automation, we can reduce the time these processes take and ensure the high-volume production required by the aerospace and automotive sectors.

Talk to usKey capabilities

We have expertise and equipment to assist companies transitions towards more sustainable thermoplastic composite materials and corresponding manufacturing processes.

Our automated processes can take cycle times down from six hours to 15 minutes, removing unnecessary manual work and ensuring the highest quality standards.

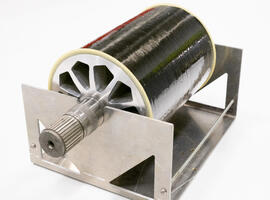

We can replace expensive pre-preg materials with bespoke woven dry fibre, making your processes more efficient and allowing high-volume production of large, complex parts.

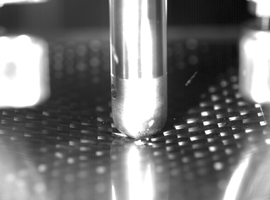

We have specialist expertise in machining composites, which often requires particular cutting tools. We’ll demonstrate how to reduce damage and ensure precise results every time.

We can embed sensors in parts, giving you valuable data about how factors like heat and stress affect your processes, and allowing you to make parts as long-lasting as possible.

How we can help your business

We work with businesses of all sizes to find solutions to their challenges. Our unique blend of academic research and significant industry experience means we can have a big impact on your processes — and your bottom line.

We have the facilities and expertise to create an entire manufacturing process, starting with a design and bobbins of fibres right through to a moulded and fully machined finished component.

From automating your production line to finding the right cutting tools, there are many ways we can improve how you do things.

We also undertake research to push UK industry forward, concentrating on the biggest challenges like sustainability and supply chain resilience.

Talk to us