AMRC helps drive forward blueprint for production rates of SMEs electric motors

27 February 2024New processes have been devised and technology de-risked by the University of Sheffield AMRC to help increase electric motor production rates for the UK’s largest supplier of electric drive systems - with an ambition of transitioning from 60 to 5,000 traction motors per year.

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) formed part of a consortium of experts tasked by Magtec, based in Rotherham, to support the business need for new ways to reduce bottlenecks within its production processes to enable an increase in the number of electric motors it could make per year.

AMRC engineers with expertise in composites and integrated manufacturing supported Magtec by successfully creating factory simulations to optimise vital decisions prior to implementing changes to production and making investment decisions, helped them adopt a towpreg winding technique, reducing set-up time and increasing throughput, as well as providing ideas and advice on alternative lamination technologies it could use in the future as the business grows.

Lloyd Tinkler, senior technical fellow who led on the project for the AMRC, said: “We are thrilled to have worked with Magtec again as a follow on from a previous five-day assist programme we did with them in 2022, which looked at their factory flow and how they could save time and money.

“This extended project has enabled us to use our expertise and delve deeper into their factory workflows and processes, complementing the work other consortium members have contributed.

“We believe our work has been useful to help Magtec on its growth journey – it has been rewarding to see them move into a bigger facility, bring in new equipment and technologies off the back of our research work and recommendations, and grow from a small to a medium-sized business in just a few short years. We look forward to seeing what they do next.”

Andrew Gilligan, managing director at Magtec, said: “Global demand for EV drive systems continues to increase at rate. Magtec has been challenged by its clients to increase production significantly and this requires a fresh perspective on how we produce our EV systems, especially traction motors, in a volume environment.

“Magtec has a strong and long-standing relationship with the team at the AMRC, so we engaged them to help us on this exciting industrialisation journey. Through the evaluation of current manufacturing methods and the adoption of best in class manufacturing processes, AMRC has helped Magtec to define its industrial roadmap, as well as embed processes which have had an immediate and long lasting effect.”

The AMRC, part of the High Value Manufacturing (HVM) Catapult, secured £350,000 of the total £5.5m project value, £2.6m of which was funded by the Advanced Propulsion Centre, which provides funding for the development of low emission transport solutions and automotive technologies – supporting the UK’s transition towards net zero product manufacturing and supply chain in the automotive sector.

Other members of the consortium included fellow HVM Catapult centre, the Manufacturing Technology Centre (MTC), Angel Trains and Dennis Eagle Trucks.

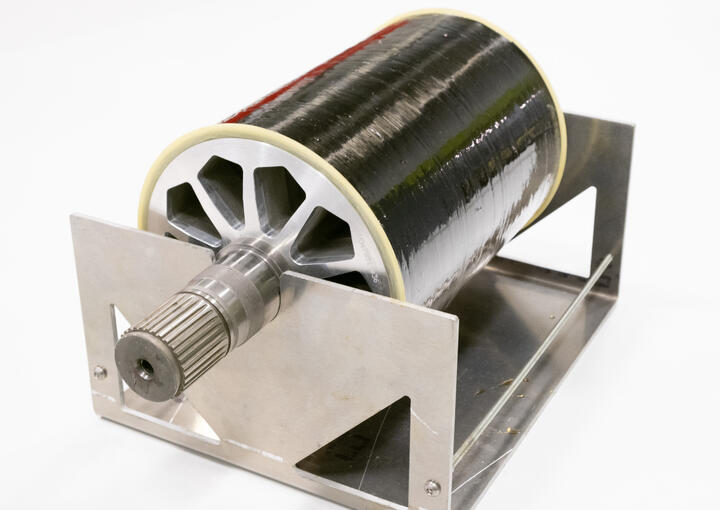

On supporting new composite technology and processes for Magtec, Jonathan Di Lorenzo, technical lead at the AMRC, said his team's work focused on in-situ filament winding of the carbon fibre rotor sleeve which keeps the magnets in place whilst spinning at high speed.

“We firstly developed a calculator to estimate the inward pressure the sleeve could apply with different fibre tensions, which ultimately limits the maximum operating speed. We also performed experimental trials creating rotor sleeves, using microscopy to compare these results to Magtec’s existing wet-wind process.

“In addition, we investigated the influence of process parameters on throughput and provided information to help Magtec with future production adoptions. The calculators helped predict the minimum amount of material and tension required and as part of this project we were able to set up the foundations for mechanically testing composite rings to verify performance, which can be useful tools moving forward.”

As a result of working with the AMRC, Magtec is set to adopt a new technology – moving away from its former wet-winding process and now utilising a different method called towpreg winding.

“The towpreg method starts with the material having the resin already impregnated into the fibre and provides better consistency, less set-up time and processing, and can result in a more stable product at the end,” added Jonathan. “This is instead of using the wet-winding process involving dipping dry fibre into a resin bath which can be messy and time consuming.

“It’s a small, but important part of the motor build process, but by de-risking the new capability method first has helped provide confidence in the technology and justifies costs that this method can contribute to helping them achieve the build rate they are aiming for.”

Scoping lamination technologies and factory simulation also played a part in the AMRC’s work.

Alongside the updated composite processes, Lloyd said the team pushed further, providing recommendations that could take Magtec forward in the future.

He added: “We also helped Magtec with providing recommendations around lamination technologies which could support them as they increase the volume of their production. As well as the rotator, a motor also has a stator, both made up of sheets of steel, stacked and glued together – and we recommended a better way of doing that, looking at alternative cutting and glueing methods they could use.

“It’s not something Magtec is looking to adopt at the moment, but there’s potential for the future and new ways of working for them to explore.”

Cansu Kandemir, technical fellow at the AMRC worked with Magtec to create a factory simulation, and analysis of its supply chain, using Siemens’ tecnomatix plant simulation technology, which helped the business to understand what critical materials and precautions were needed to help validate and optimise their decision processes prior to production.

“We were responsible for integrating advancements to their factory floor via a virtual simulation and provided recommendations and support to enable the business to reach its ‘Blueprint 5000’ to create 5,000 motors per year," said Cansu.

“We looked to see how everything was working and if it was coherent with the rest of the production floor and to see if bottlenecks were cleared.”

The simulation was also able to plan out how many machines would be needed to enable Magtec to reach its aimed production goal. First, the team devised a baseline model that represented what went on in the facility currently and then added in new advancements, automations and new technology.

“At the beginning we didn’t have the exact process of their new operations, so we had to make some initial assumptions and came back with pessimistic and optimistic estimations,” added Cansu. “As a result of this, we created two models to reflect this and we were able to come up with the optimum number of machines and/or workers needed and gave them a profile to follow on how to achieve the blueprint 5,000 motors per year.”

As Magtec began purchasing new equipment off the back of projections coming from the simulation, the team was able to update the simulation model accordingly to ensure the projected production rate remains on track.

Alongside the updated composite processes and factory simulation creation, Lloyd said the team pushed further, providing recommendations that could take Magtec forward in the future.

Andrew Sloan, engineering director at Magtec said: “Magtec are committed to developing and manufacturing the best EV drive systems to meet the challenging demands of commercial vehicle operation.

“The team at the AMRC and Magtec will continue to work together to eliminate the limitations in our manufacturing processes, implement new and class leading technology and enable competitive industrial growth of traction motor production in the UK”.