Sensing data-driven decisions

Structural health monitoring of composite components typically starts when the part enters service and monitoring equipment is usually bonded onto the surface of a composite. However, a parts life begins long before it enters service and to gain the most value, monitoring needs to begin at manufacture.

Added to this, a greater focus is being placed on traceability during the manufacturing process, with process data becoming essential to the diagnosis of longer-term, inservice failure or performance reduction of components.

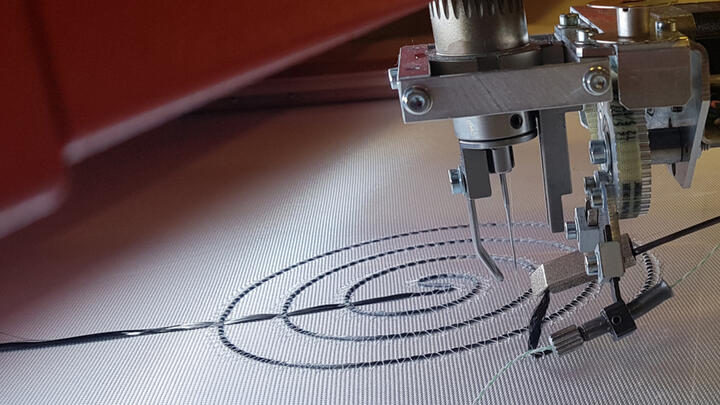

In a 12-month, High Value Manufacturing (HVM) Catapultfunded project, engineers at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) Composite Centre investigated different strategies to integrate sensors in the earliest stage of the manufacturing process.

By embedding sensors inside the material, manufacturing processes such as infusion, cure and machining, can be verified through collected data. Without embedded sensors, this monitoring of manufacture and in-service performance would not be possible.