The electrification gold rush

23 February 2022Professor Geraint Jewell, a leading expert on electrical machines, explains the vast opportunities for electrification at the AMRC and why his two-year secondment from the University of Sheffield should set a precedent for other academics.

Article featured in issue 14 of the AMRC Journal – out now

“Electrical machines are in a boom time right now. With the global net zero agenda and a huge push from industry, it’s like the gold rush.”

If anyone knows about the potential of electrical machines then it should be Professor Geraint Jewell. With a CV that would be the envy of many academics, he is director of both the Future Electrical Machines Manufacturing (FEMM) Hub and the Rolls-Royce University Technology Centre (UTC) in Advanced Electrical Machines and Drives; academic in the Department of Electronic and Electrical Engineering since 1994; and now on secondment at Factory 2050 to drive forward the University of Sheffield Advanced Manufacturing Research Centre’s (AMRC) goals to support zero emission flight.

“Researchers are almost plateauing in what they can do with classical research on electrical machines. The biggest opportunities in the UK research landscape now are around their manufacture rather than squeezing out another one per cent of efficiency, or developing a new model, because that is kind of levelling out now,” said Geraint.

“There is huge potential in this area and some large opportunities to grasp that can carve out a position for the AMRC that complements both the outstanding work being done at the University of Sheffield and the capabilities of other High Value Manufacturing (HVM) Catapult centres. That is what has brought me to the AMRC.”

Geraint has a 36-year association with the University of Sheffield which started as an undergraduate in the Department of Electronic and Electrical Engineering in 1985 and progressed onto the academic staff in 1994.

Alongside mainstream academic roles within the department and the directorships at FEMM Hub and the Rolls-Royce UTC, he has served as the Faculty of Engineering’s first faculty director of research and innovation, from 2008 to 2011, and as head of the department, from 2013 to 2019.

The majority of Geraint’s research has been directed towards aero-engine applications in collaboration with industry leader Rolls-Royce. This research has included high temperature devices and several demonstrator starter- generators for aero-engines. Geraint says the UK has a very strong international standing in electrical machines research.

“The UK is very strong internationally in research into electrical machines and Sheffield, in terms of permanent magnet machines, is amongst the best known groups in the world.”

South Yorkshire’s pedigree in engineering and in electrical machines is now bearing tangible fruit through the work of the Rolls- Royce UTC and two successful spin outs from the university’s Electrical Machines and Drives (EMD) group. Rotherham-based drives systems manufacturer, Magtec, is targeting sales of £30m in 2022; while Sheffield-based Magnomatics’ revolutionary magnetic gears are used in all manner of sectors, from marine propulsion to renewable wind energy.

Electrical machines are in a boom time right now. With the global net zero agenda and a huge push from industry, it’s like the gold rush.

While those spin outs are examples of the outstanding track record for innovation and successful commercialisation of the EMD group from the Department of Electronic and Electrical Engineering, pioneering research into electromagnetics, Geraint says it has become clear in recent years that electric machines need to be approached from a manufacturing perspective as well.

Enter, the Future Electrical Machines Manufacturing Hub.

The £28m, seven-year programme, which began in 2019 and is core- funded by the Engineering and Physical Sciences Research Council (EPSRC) with supporting contributions from a range of industry partners, is developing new manufacturing techniques and technologies to improve the reliability and performance of high value electrical machines. Researchers are working closely with an industry advisory board and scientific advisory board to address key manufacturing challenges in the production of electrical machines to put UK manufacturing at the forefront of the electrical revolution.

The hub is a consortium of five research groups from three institutions: the University of Sheffield’s AMRC, EMD group from the Department of Electronic and Electrical Engineering; and the Department of Automatic Control and Systems Engineering (ACSE); the Electrical Power group at Newcastle University; and the University of Strathclyde’s Advanced Forming Research Centre (AFRC), part of the National Manufacturing Institute Scotland.

Geraint says when the consortium wrote the bid for FEMM Hub, there was little coordinated or sustained activity in electrical machine manufacture of any note in the UK and, indeed, it was not recognised as a discipline in its own right.

“Three of the five partners have a manufacturing background and two have backgrounds in electrical machines. They had not previously worked together and it was deliberately pitched to the EPSRC in that way,” said Geraint.

“Each part of the consortium is very strong at what it does, but never had a mechanism to work together. That was the central message of the bid.”

The AMRC is hosting the majority of FEMM Hub’s capital investment at Factory 2050 in Sheffield. Two winding robots and a remote laser cutting facility have now been established.

Geraint said: “Currently, 5 kW/kg is a very good continuous power density for an electrical machine, but if the UK is to truly make electric flight a reality in the next 15 years, that needs to get up to 15 or even 20kW/kg.

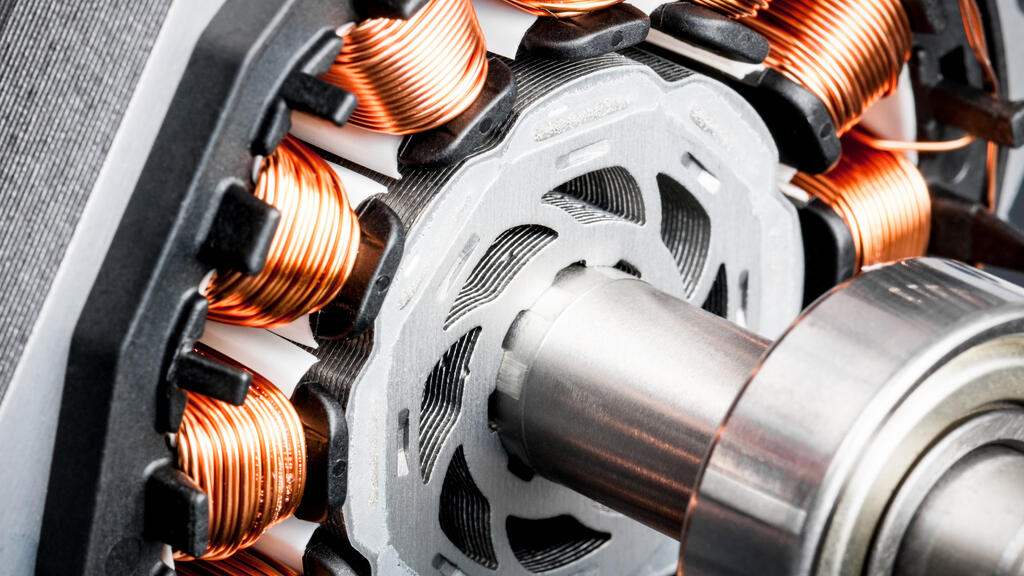

“When producing an electrical machine there are two distinct aspects: the magnets, coils and cores where the ‘magic’ happens, and the structural elements which play a key role in mechanical integration thermal management. A key focus of the FEMM Hub is research into advanced materials and advanced manufacturing to reduce weight in the structural parts of a machine – the casing, the shafts and hubs. These have as big a role to play in increasing power density as advances in the active regions of the machine.

“If you look at the materials in a state- of-the-art high performance electrical machine: the stator core material tends to be a Cobalt-Iron alloys, which in essence is an incremental development on permendur, which was discovered in 1932; the magnets are samarium cobalt, which has been around since the late 1960s; and the wire is drawn copper wire, which Theophilus the Monk was documenting in the 12th Century. An electrical machine designer’s palette of materials is very static, so the idea that the magnetic aspects of a machine is going to get us that doubling of power density over the next 15 years is for the birds – we’ll do it through developing the structural elements and in particular thermal management. Longer-term, more usable superconducting material may provide the step change in active materials within a machine but even then, they will remain a niche option if any form of cryo-cooling is required.”

The nature of the FEMM Hub consortium, bringing together academics and engineers with disparate backgrounds, means a skills programme has slowly developed, largely through necessity.

“It started because half of our team were manufacturing engineers and the other half electromagnetic engineers, so we needed to teach one half what the other did,” said Geraint.

“The first course I did was for about 40 people across the hub and our industry partners. That has evolved now to half a dozen training courses a year, attracting over 100 people with 80 per cent of those coming from industry.

“FEMM Hub doesn’t have a specific remit to address talent and skills in this area, but we have a vibrant skills activity which has grown due to the demand from our industry partners. There is a massive thirst for courses in this area and even though we are EPSRC-funded, we have to keep our industry partners engaged and convinced there is good value in continuing to work with us.”

Now, alongside that work with FEMM Hub, Geraint has begun a two-year secondment from the University of Sheffield’s Department of Electronic and Electrical Engineering to the AMRC, bringing with him a wealth of experience and unparalleled familiarity with electrification.

“Electrical machine manufacture, certainly in the UK, is a low profile and small-scale subject academically,” said Geraint. “But, as we’re seeing with FEMM Hub, there are massive opportunities to lightweight the structural aspects of electrical machines. Working closely with the AMRC’s CEO Steve Foxley, research director Ben Morgan and technical fellow in electrical machines Lloyd Tinkler, I want to build up the AMRC’s electrification capability and really push onto the next stage.

“Electrification doesn’t have its own pillar in the AMRC’s ten-year strategy, but it is central to the theme of Future Propulsion. Drawing on my experience in electrical machines, one of the first things I am doing at the AMRC is writing a plan of action in this area from which we can pull elements for proposals.

“There are some big decisions to be made soon about what the scope of capital investment is going to be and what the AMRC’s role in this space is going to be. My background is largely working with Rolls-Royce, so there is a lot of potential with aerospace, but we also need to investigate electric machines for other sectors that require high-power and high added-value electrical machines such as off-highway vehicles, rail, marine and renewables.”

Geraint says he will benefit hugely from spending half his time at Factory 2050 and working much closer with the AMRC’s engineers.

He said: “I’ve had links with the AMRC since it started in 2001 and have always felt at home here. There is the ambition at the AMRC that doesn’t always exist elsewhere which allows us to go out and bid on a large scale for big investment.

“The AMRC directors will hopefully benefit from my input to build a strategy for electrification and the Department of Electronic and Electrical Engineering should profit from having a direct link into the AMRC. Really, this secondment should benefit every part of the Faculty of Engineering.”

For Geraint, there is the additional value of setting a precedent he hopes other academics at the University of Sheffield will follow.

He said: “I’m hoping to demonstrate to my colleagues more widely, not just with the AMRC, the value of not just meeting up once every six months saying ‘we should work together’ but putting someone on the ground, making it real - that’s a formalism you need to be able to do this properly.

“It’s something I would like to see more of, but only when it has got a prospect of being good for the individual, good for the home department and in this instance good for the AMRC.

“I might be the first one, but I don’t want to be the last.”

Article featured in issue 14 of the AMRC Journal – out now