Pioneering composite inspection technology

18 August 2020A vision inspection system using 3D modelling could save composite manufacturers valuable time and money by eliminating the manual inspection process of composite materials and parts, according to researchers at the University of Sheffield Advanced Manufacturing Research Centre (AMRC).

“Quality checks during the lay-up process are vital but can take 70-per-cent or more of total machine time,” said Zeeshan Qureshi, Lead Research Engineer on the Design Analysis and Composite Automation team at the AMRC Composite Centre.

“It is a huge cost to our partners so we’re investigating automated in-process inspection systems that could help significantly decrease, or even eliminate entirely, manual inspection in order for them to achieve higher productivity in their factories.”

Composite components are made by layering plies of unidirectional fibres or woven fabrics, which are then cured to produce a final solid part. The strength of the part is dependent on the correct alignment of the fibres from which it is made; fibres which are laid incorrectly can result in a range of defects that affect the structural integrity of the final part.

Detecting such defects, from gaps and overlaps to the presence of foreign objects and debris, at the relatively early lay-up stage of production is much more efficient and cost effective than identifying unacceptable weak points in the material once it is part of a completed component.

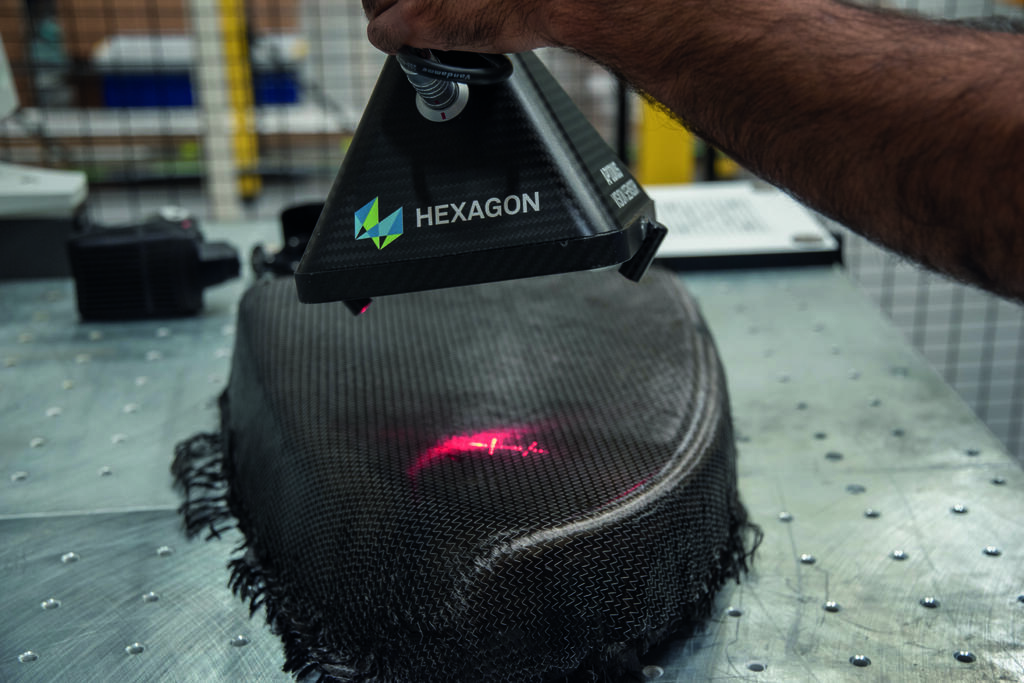

Zeeshan said the Composite Centre researched what systems were being successfully employed in related applications which identified the capabilities of the Absolute Arm and its laser scanner options, products developed by Hexagon’s Manufacturing Intelligence division.

“We discovered that Hexagon have developed a composite inspection system specially for measuring fibre orientations, which we believed could be a potential candidate for solving some of our inspection problems. They were quickly able to bring one such system to the AMRC to perform a case study – an Absolute Arm with RS5 Laser Scanner and a Vision System 3D,” said Zeeshan.

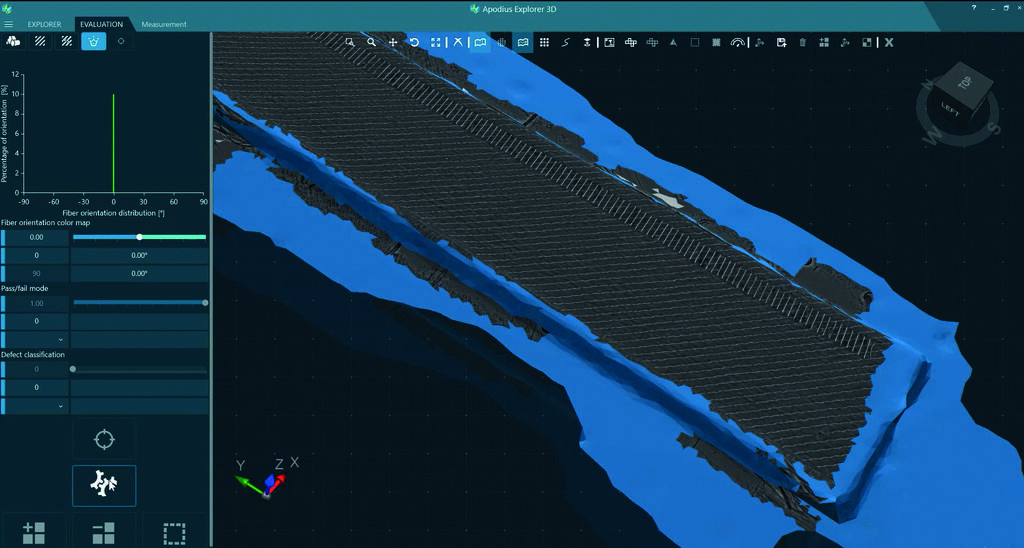

The Vision System 3D is a camera-based sensor that can accurately detect the orientation of composite fibres using pixel based algorithms. The system uses a metrological Absolute Arm for position referencing and, combined with scans made using the arm’s laser scanner and camera functionalities, this fibre orientation data can be mapped onto a three-dimensional model of the part being inspected using the dedicated Explorer 3D software platform.

“The system lets us validate the design and simulation work that we do at our desks to make sure our design intent is being manufactured, so it becomes a good validation step for our design and manufacture process,” said Zeeshan.

“We’re primarily using the system for weaving, braiding and preforming processes. Once we perform that initial manufacturing process, we can bring the part to the workstation and we would use the new inspection system to do a scan of the part to generate the 3D profile of the part we have.

“Using some of the advanced algorithms that are built into the software, we’re then able to determine fibre orientations that can give us an indication of some of the defects that are present in the part.

“We can take that information back into our design and analysis software to update our models with the data from the as-manufactured part in order to perform an analysis which we can then compare against the as-designed part. This provides valuable information for comparing the ‘real’ and ‘virtual’ environments in which we work.”

The Vision System 3D is one of a number of solutions for composite fibre inspection that has been developed by Hexagon’s Vision and Composites product group in Aachen, Germany.

“Working closely with the AMRC Composite Centre has been incredibly valuable to us here at Hexagon,” said Alexander Leutner, Director Vision at Hexagon. “It’s great to see our Vision System technology being used to enable the next leaps forward in the industrialisation of composite production, and the feedback we receive from the AMRC team has been invaluable to us as we continue to develop and improve our solutions.

“We’re in regular contact with Zeeshan and his team, and that close partnership has helped us to develop system enhancements, new software modules and applications that we hadn’t previously thought about.

“It’s also been incredibly interesting to work with the AMRC in taking this research into the world of automation, with inspection built into the fibre placement or tape laying processes. I’m really looking forward to seeing our partnership develop even further, especially with the studies the team are now performing with our automated AFP Inspection System.”

Zeeshan said the next stage of the project is to investigate how the technology can be applied in other areas: “This is the first time we’ve had a metrology inspection system in-house. Now we’re hoping to help further develop both the hardware and software systems to make them robust enough to pick up some of the more complex defects that we’re hoping to achieve solutions for in the near future.

“One of the advantages of having this system is that the sensor can be integrated with other composite lay-up machines as well, such as the AFP machine, braiding, stitching, or 2.5D or 3D weaving machines that we have at the AMRC with the aim of achieving online inspection systems.”