Jewel in the crown

17 June 2020A watch-style bracelet made from ‘space glass’ that has a custom, uncut diamond in its crown could be the centrepiece of a new luxury lifestyle brand, thanks to design and machining experts at the University of Sheffield Advanced Manufacturing Research Centre (AMRC).

The sophisticated piece of jewellery is the brainchild of entrepreneur and open-banking specialist Steffan van Molendorff, who has taken his passion for motorcycles, engineering and diamonds and used them as inspirational fuel for his adventure lifestyle brand, 6ixt9 (pronounced sixty-nine).

The 50-year-old South African has big ambitions for the brand and one of the concepts he is currently developing is a bracelet which looks just like a regular watch except in the place of a clock face sits a raw, uncut diamond.

The idea was little more than a pencil drawing on a scrap of paper when AMRC machine tool partner Starrag put Steffan in touch with engineers at the AMRC in Rotherham, which is part of the UK’s High Value Manufacturing (HVM) Catapult network of world-leading research centres.

It is there that machining research engineer Emma Parkin, together with design and prototyping engineer Valdis Krumins, began work on turning the rough sketch into a reality.

The designs they created have ‘exceeded all expectations’, says Steffan.

“I knew from early on that one of the products I wanted to do was something really unique and different and aimed at a very niche, sophisticated market,” he said. “That’s how I came up with the idea of taking a rough diamond and putting it inside a watch casing.

“I came to the AMRC and met Emma and Valdis, sharing with them an idea and a simple paper drawing. About two weeks later the first CAD designs came through from Valdis and they were amazing. At that stage I knew we were on to something special and unique.

The whole process has been fantastic. Emma and Valdis have been so supportive and creative in coming up with ideas. They have been wonderful to work with.

“Emma spoke so enthusiastically about the machining process and the different materials we could make the watch-case from - that’s when she told me about Zerodur®, a type of glass-ceramic that can be machined and is used a lot in space applications. I loved the idea of having ‘space glass’ as the material for the watch casing.

“The whole process has been fantastic. Emma and Valdis have been so supportive and creative in coming up with ideas. They have been wonderful to work with. The designs which Valdis completed have now been registered for design protection in the UK and EU and I’m very excited to work with the AMRC team on this project and look forward to an interesting future."

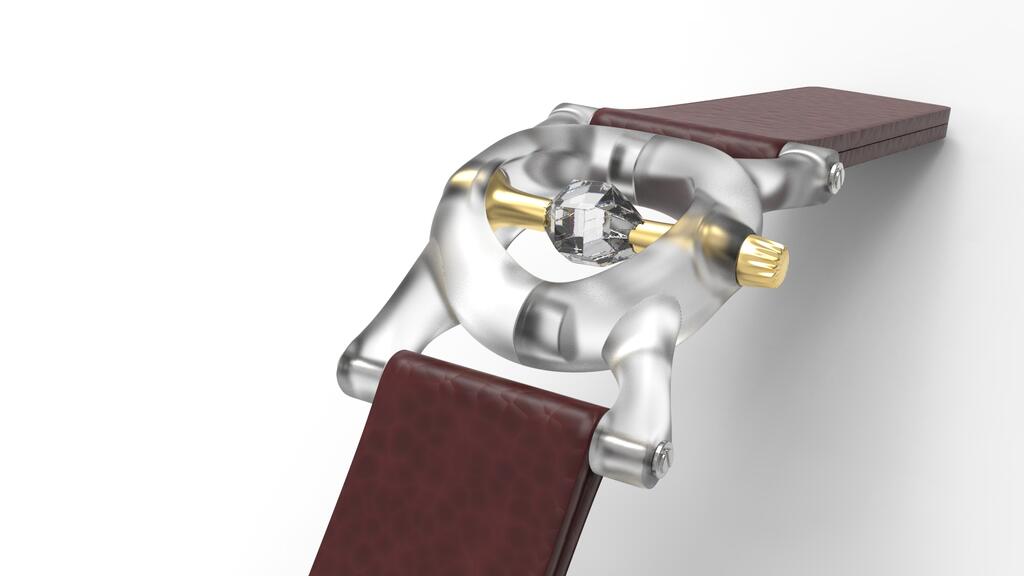

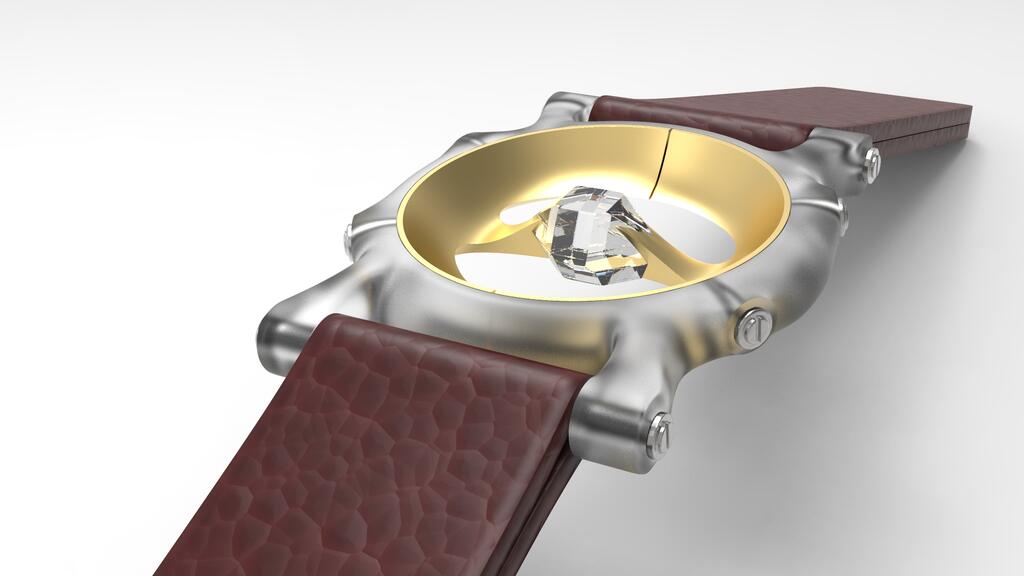

The three ideas consisted of a ‘crown’, ‘slim’ and ‘rectangular’ designs, as Valdis explained: “The ‘crown’ is inspired by the 6ixt9 brand itself. The curves of the logo and bikes are smooth while the leather accessories are chunky and honest. It lets the stone not only be displayed proudly but also admired in full 360 degrees by rotating the crown.

“The ‘slim’ is designed around not exceeding the height of the stone. Imagine a dress watch, if you will, which slides under the cuff of a shirt almost unnoticed. There are no layers of components as all the structural interfaces are designed to assemble flat in one plane.

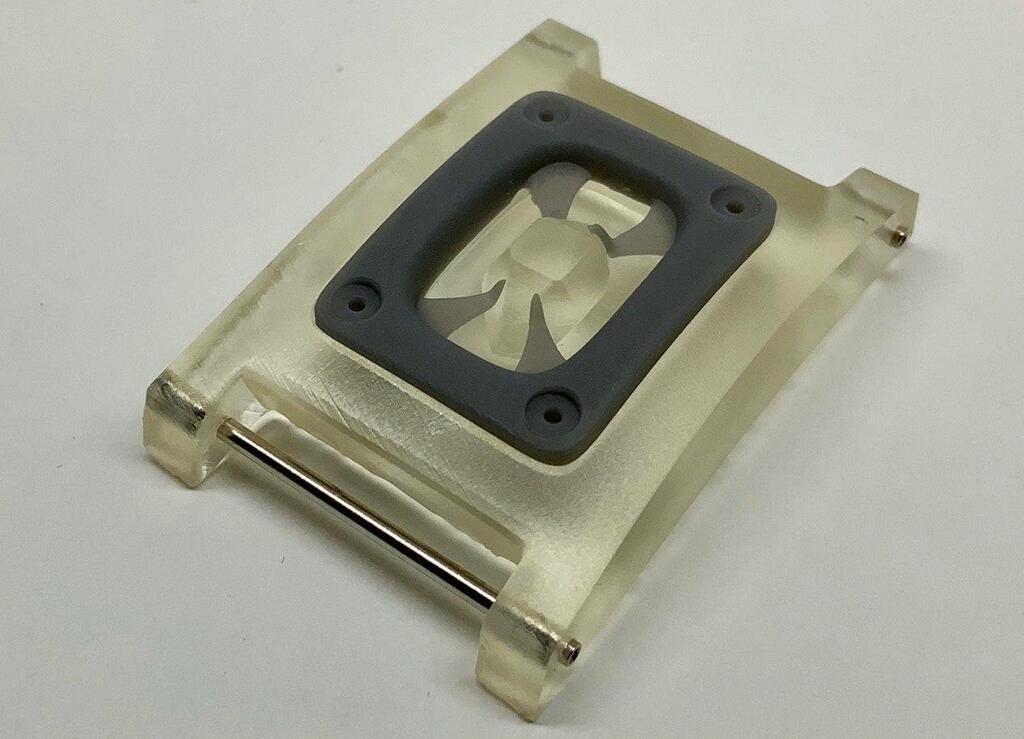

“The ‘rectangle’ stems from a drawing by Steffan that he showed me when we first met. The resulting design is a middle ground between the flashy ‘crown’ and subtle ‘slim’ designs. The ‘rectangle’ is the one we selected to prototype.”

The machining work for the prototype is on hold due to coronavirus restrictions but the extra time has allowed Emma to carry out further investigation into UK suppliers of the Zerodur® material, which is manufactured by international technology group Schott. She is also exploring suitable cutting tools and machining strategies.

Emma said: “The favoured machine for the work is the DMG Ultrasonic 10 that we have here at the AMRC. It’s a small machine more commonly used by dental laboratories to make dental prostheses such as bridges and crowns. It’s perfect for machining hard materials like glass.”

Dr David Curtis, AMRC Technical Fellow for abrasive processes, said due to the material being an engineered glass-ceramic - which is brittle, has an extremely low coefficient of thermal expansion and a hardness similar to borosilicate glass – careful consideration of the machining process is required.

With ultrasonic grinding, the cutting tool oscillates at a fraction of the width of a human hair at a rate of 25,000 times per second,which acts to reduce forces and increase achievable material removal rates.

“Techniques developed for satellite mirror grinding may need to be utilised to manage brittle to ductile material removal, controlling subsurface defects that are generated for aesthetic rather than functional performance,” said Dr Curtis. “The DMG Ultrasonic 10 platform will allow us to explore material removal strategies for a range of feature geometries, material removal rates and surface quality requirements with both conventional diamond grinding and ultrasonic assisted methods.

“With ultrasonic grinding, the cutting tool oscillates at a fraction of the width of a human hair at a rate of 25,000 times per second, which acts to reduce forces and increase achievable material removal rates. A balance between efficient stock removal and surface / subsurface quality will likely be required for this application.”

Emma said three to five prototypes will be made which Steffan can use to market his jewellery idea. She added: “Part of the project will also involve documenting everything we do so we can create a knowledge transfer pack that can be shared with Steffan so he can take that information away with him and know what machines need to be used, which cutting tools, and have a detailed method of manufacture for his product.”

With a price tag of between £10k-£12k, and even up to £100k depending on the level of customisation, Steffan’s jewellery does not come cheap.

“You can’t use small diamonds in the bracelet itself because of the design and size, so you’re looking at using three and four carat quality stones. The target for this product is high net worth individuals, markets in the Middle East, Far East and perhaps New York.”

One day someone showed up to dad’s work and said he thought there were diamonds on the farmland he owned and wanted to do some prospecting. A nine carat diamond was found on the land and that changed the whole dynamic forever.

Steffan is no stranger to the lucrative diamond industry. His family’s farm in South Africa was mined for diamonds for a short period after a prospector discovered a nine carat stone on their land, changing the family’s fortunes forever.

“I grew up in an engineering environment, my dad had a company in South Africa manufacturing heat exchangers for the mining industry. One day someone showed up to dad’s work and said he thought there were diamonds on the farmland he owned and wanted to do some prospecting. A nine carat diamond was found on the land and that changed the whole dynamic forever.

“The farm was mined for about 18 months. It wasn’t very yielding, the operational costs were quite high in terms of the diamonds recovered. After 18 months we gave it up and I moved into the rough diamond trade and travelled through Africa looking for diamonds. But it was a tough industry to operate in and I didn’t have enough capital to compete so I had to stop.

“But what it did do is plant the love I have for rough diamonds. I wanted to take that love, and my passion for motorcycles and engineering, and use my creative side to build these into a lifestyle brand that is bold and different. It took me a while to find the courage to do it but that’s how 6ixt9 was kick-started into life.”

The project, paid for by the AMRC using funds from the High Value Manufacturing (HMV) Catapult, is part of the AMRC’s commitment to supporting smaller and medium sized businesses.