'Game-changing' potential for additive manufacturing

04 January 2023The University of Sheffield Advanced Manufacturing Research Centre (AMRC) North West is working with Theta Technologies to investigate its new non-destructive testing (NDT) product which the company says is a game-changing development for metal additive manufacturing.

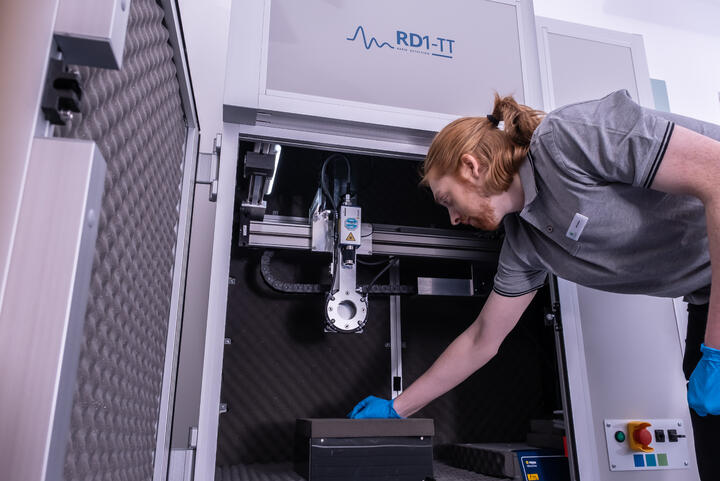

Theta Technologies has developed its first commercially available NDT product, the RD1-TT, to provide a cost-effective, rapid flaw detection solution for metal additive manufacturers. The company is collaborating with AMRC North West and BAE Systems to test the suitability of the product for testing a range of BAE Systems components.

The technology has the potential to have a significant impact on the future of metal additive manufacturing testing processes, particularly for parts produced for critical applications in industries such as defence, aerospace, automotive and nuclear energy.

AMRC North West research director, Dr James Hughes, said: “We are very excited to participate in this project to test the feasibility of this new NDT technique developed by Theta Technologies, and to assess the usability as an evaluation tool needed to address the quality control challenges encountered in AM.

“As a part of the consortium, AMRC North West will work on the measurement system analysis and applicability of the technique on a wide range of products with different materials and geometries provided by BAE Systems.”

Steve Butler, CEO of Theta Technologies, says it is a significant step forward for the company, not only when it comes to validating the technology, but also to assist in the development of future products.

“AMRC North West has the expertise we need in the research and development of metal additive manufacturing and working with their high-performing technical R&D team will help us achieve and deliver on our ambitions to develop a game-changing solution.

“To have BAE Systems, a major international manufacturer, express such an interest in our technology is a tremendous boost for us. This collaboration will help us to gather further evidence of our technologies’ capabilities and allow us to validate what we know it can do.”

Steve added: “It’s extremely important for us to use this project to understand the challenges that manufacturers face with regards to their manufacturing and testing processes so that we can continue to develop existing and future products to maximise the benefit to our customers.”

Kevin Pickup, lead technologist for product verification, BAE Systems Air sector, said: "As we evolve our manufacturing processes we recognise new opportunities and advances in inspection capability. New and novel methods of verifying the product has been made correctly, right the first time and aiming for no fault forward are something we are always looking to explore and exploit. We are impressed by Theta Technologies innovative NDT methods and excited to work together to assess the RD1-TT, to understand how it can be effectively embedded within our production lines, and across our product range."

As a result of the industrial research collaboration, an RD1-TT unit will soon be based within the AMRC North West facility in Samlesbury, where it will be testing a variety of BAE Systems’ manufactured components, including 3D printed metals and composites.

AMRC North West is a part of the University of Sheffield Advanced Manufacturing Research Centre (AMRC), which is a member of the national High Value Manufacturing (HVM) Catapult network of research centres.