From couture to composites: spinning a high-tech yarn

22 April 2021Fabric producer Antich and Sons has achieved a step change in its manufacturing capability to produce finished 3D multilayer woven preforms for advanced composites used in aerospace and automotive through a pioneering project with the University of Sheffield Advanced Manufacturing Research Centre (AMRC).

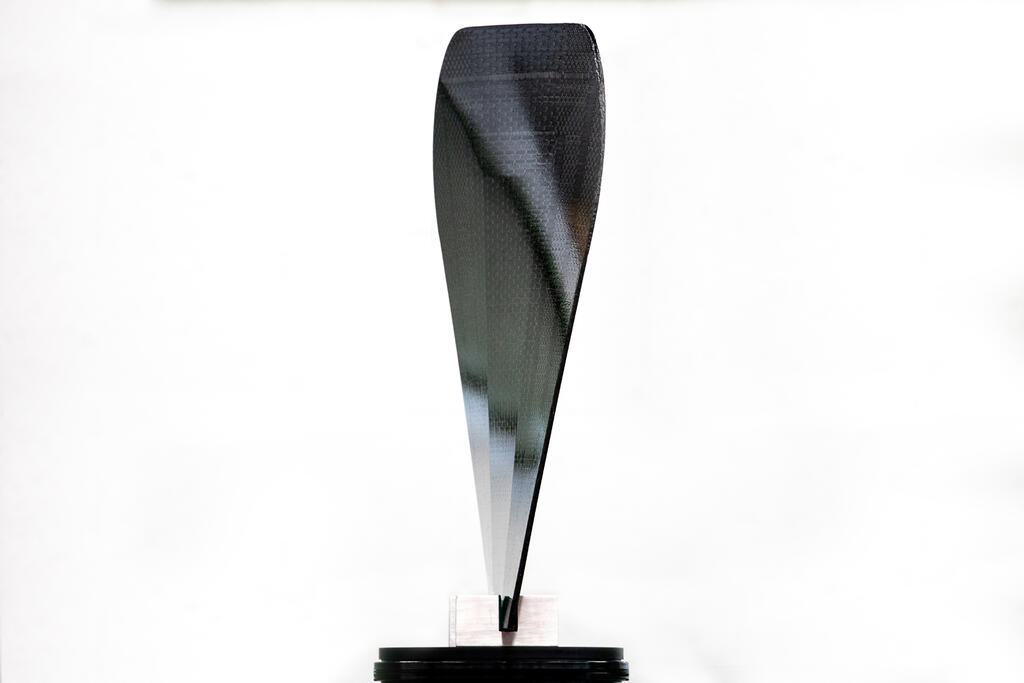

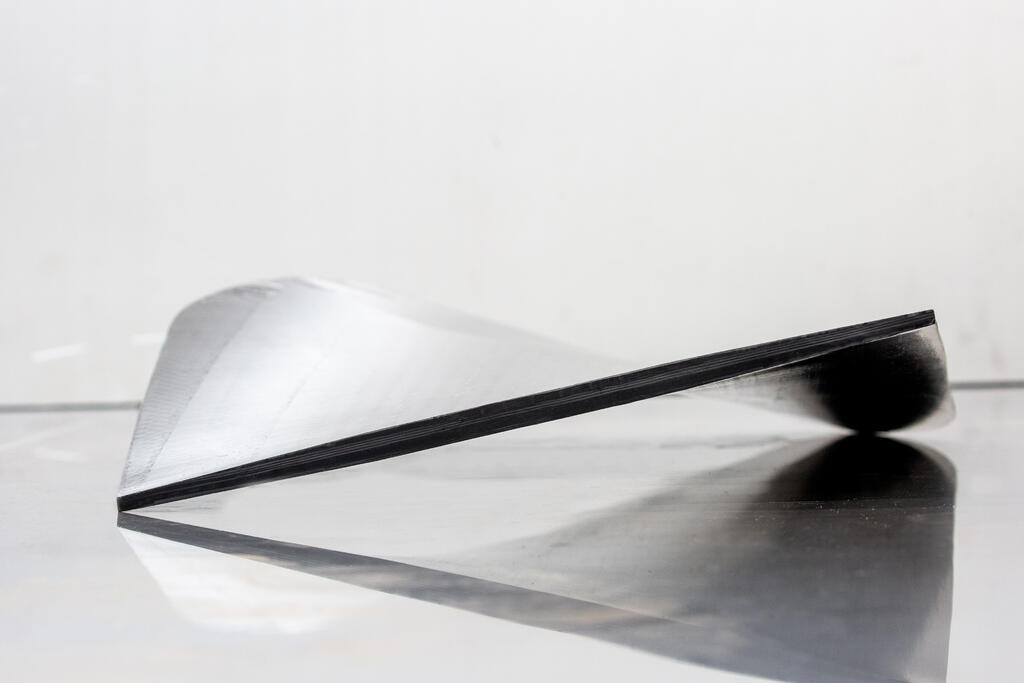

3D weaving of carbon fibre is a cost-effective method for producing high-quality, damage tolerant, large-scale, and high-thickness laminates for use with liquid resin injection processes to make lightweight composite materials. However, to create composite preforms suitable for resin transfer moulding, several additional processes are key for widespread adoption of the technology.

Antich and Sons’ advanced capability is the culmination of FABFORM, a three-year project undertaken with the AMRC and funded by Innovate UK, which focused on developing the additional methods needed to create stabilised, near-net shape preforms of variable thickness. These preforms will allow for efficient use of material within a component, ensure the correct size and shape to drop into moulds used for injection of composite matrix resin, as well as facilitate an easier and more robust handling and transport.

Antich and Sons sits in the northern textile heartland of the UK and has more than 30 years’ experience of weaving fine worsted cloth and making bespoke tailored suits. It is considered the best-known commission weaver, warper and mender of the Yorkshire fine worsted industry, producing cloth for some of the top fashion houses such as Prada, Armani, Givenchy, Lanvin, Boss and Chanel.

The company’s head of research and development, Andy Smith, said developments in the stabilising and trimming of 3D woven carbon fibre preforms with uniform and variable thicknesses is a significant achievement for the Huddersfield-based company, moving it beyond the current state-of-the-art and providing a step change in the UK manufacturing capability.

“The variable thickness, stabilisation and trimming methods developed for 3D woven materials in FABFORM allow a significant step up the value chain,” said Smith. “It takes Antich from a weaver of fabric to a manufacturer of advanced composite preforms ready for the next step in the manufacturing process.”

The development of key processes necessary to transform 3D woven fabrics into ‘mould ready’ preforms is still immature in the UK supply chain. Smith said the new developments by Antich and Sons bring great value to the market by advancing manufacturing technologies, improving product performance and streamlining production capabilities.

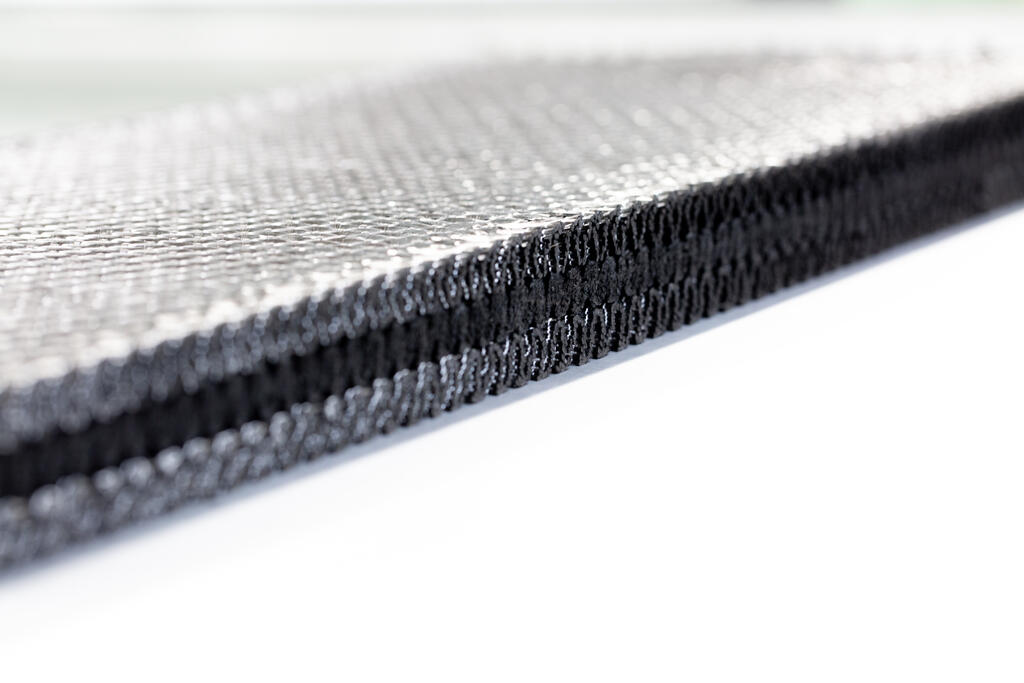

“In the past, 3D woven preforms were hard work to prepare for moulding operations and were also liable to deterioration when handled and cut,” said Smith. “We therefore felt it was crucial that, as a weaver, we developed the technology both during-and-post-weaving to supply finished, stable preforms which can be easily utilised by end users.

“The ability to access the world-class facilities at the University of Sheffield AMRC was a major help in taking a scientific approach to assessing, down-selecting and testing the right technologies as well as developing the processes on industrial scale, high-tech equipment.”

Chris McHugh is dry fibre development manager at the AMRC Composite Centre, a world-class research institute which brings expertise in composite design and manufacturing development across a wide spectrum of different technologies including dry fibre preforming, automation methods, moulding, curing, inspection, and testing.

McHugh says the developments achieved through FABFORM support the creation of more competitive products that are lighter, stiffer, and stronger, as well as helping diversify income streams, creating new jobs and increasing the skills base in composites.

He added: “The collaboration between the AMRC and Antich and Sons has utilised the combined advanced technologies and experience available to advance 3D weaving preforming capabilities for UK manufacturing. The outputs from the project have the potential to generate significant new business and strong exports for the UK, in cross sector high-value manufacturing applications including the strong export markets in automotive and aerospace.”

Smith said FABFORM has been ‘an excellent first step’ in utilising key technologies such as thickness tapering, stabilisation, and edge trimming that mechanically convert 3D fabric into a useable preform for a composite moulding operation.

He said the know-how of this project has been developed by investigating various preform stabilisation techniques and quantitatively assessing their performance through multiple test methods such as edge fraying tests and picture frame shear tests to name a few. This was followed by the comparison of a wide range of trimming methods of the preforms including laser, water jet cutting and ultrasonic methods.

“The capability to supply advanced and ready-to-go preforms opens up new avenues for the development of alternative structural and complex materials on the UK market, enabling the creation of more competitive products,” said Smith. “Future opportunities in markets such as renewables (wind turbine blades), rail (body structure), industrial processing and defence will provide long term benefits for the wider UK composite sector.”

With more than ten years’ expertise in composite research and development, in areas like polymer–matrix composites (PMC) and aluminium-matrix composites (AMC), Antich and Sons continues to drive the business forward into new applications for its weaving technology.

It has acquired a state-of-the-art single rapier 3D weaving machine from Lindauer Dornier GmbH, including a Horizontal Take Off (HTO) platform which is the first of its kind in the UK. This HTO platform enables a continuous draw of fabric off the machine in a straight horizontal configuration, instead of around a roller, which is key to avoid distortion with thick fabrics, and forms the basis for layer separation techniques that facilitate variable thickness. Capability for resin transfer moulding of prototypes has also been added to speed up development cycles.

Antich and Sons intend to exhibit at Advanced Engineering and JEC World when the conferences return.