Engineers make fashion their bag

29 August 2019Fashion isn’t the usual forte for AMRC engineers – more used to grappling with aerospace and automotive challenges than next season’s catwalk designs – but they got in touch with their creative side when a Doncaster entrepreneur asked for help in realising her dream for a new clutch bag.

Sarah Chappell, founder and director of Trilogi Fashion Ltd, which designs and creates new accessories as alternatives to so-called fast fashion, came to the AMRC armed with an idea and a sketch for a new type of clutch purse featuring customisable covers that can be changed to match any outfit.

Sarah asked the AMRC, part of the High Value Manufacturing Catapult, for help refining the bag’s frame concept and to come up with the best manufacturing processes to turn her dream into a reality.

She was not disappointed.

Peter Oates, Senior Design and Development Engineer with the Design and Prototyping Group, went far beyond Sarah’s expectations, producing physical prototype parts for the clutch bag frame.

I can honestly say what I saw far exceeded my expectations. This was my dream becoming a reality and a huge stride forward for my business.

Peter said: “Sarah came to us armed with a concept and some drawings for a new type of clutch bag she wanted to develop that has changeable covers, so you can clip on a fabric or a covering like that, to match the outfit you’re wearing.

“She had played around with a couple of concepts but had not come up with anything physical, she just had a few sketches of what she wanted to create. She was looking for a way to make it relatively simply and also have it where she could make it scalable for production.”

For Sarah, the biggest barrier was her lack of knowledge of CAD and metal manufacturing processes to take her product to a manufacturer for feasibility completion.

“I approached the AMRC for assistance with the design for manufacture part of the project,” she said. “After describing my issues, the DPG were confident they could assist. I provided my brief to the team on what the bag needed to do in terms of function, the materials required and the aesthetics it needed to meet, and they got to work.”

Peter looked at products already on the market similar in function, such as cigarette cases made from sheet metal boxes, but discarded this idea due to the manufacturing processes involved.

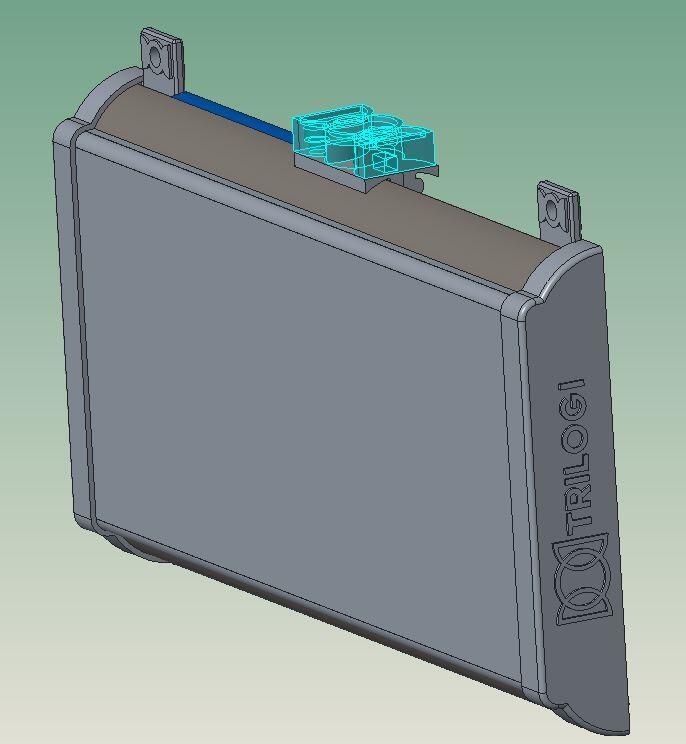

Instead he came up with the idea of using aluminium rails for the frame – which can be made to whatever length required – and making end caps for it. The bag has a standard profile within which you can fit a live hinge at the bottom, incorporating it into the design.

Peter said: “There is also a rail at the top where you can slide a catch in for closing the bag, which can be a magnetic or a sliding catch, whichever is preferred. You can also slide a set of lugs in for putting a shoulder strap on the bag, which was one of the specifications Sarah had, then you can either press or glue the end caps on. We actually came up with all of these parts, which I don’t think Sarah expected us to do. We developed three concepts to semi-prototype stage and she was able to take these away with her and piece it together.”

When Sarah came to view the solution, she was delighted. “I can honestly say what I saw far exceeded my expectations,” she said. “I did expect to see an on-screen CAD model of what my bag would look like and some information on the manufacture type of process I would need to source, but what I got was a selection of 3D-printed prototypes of my product to actually test, see and feel. This was my dream becoming a reality and a huge stride forward for my business.

“What I had not expected, and this may be my stereotyping, is for the design I was given to be so appealing in its aesthetic for a ladies’ bag from a gentleman who had never designed a bag fashion item before.”

As a group we really enjoy working with SMEs and it makes life a little more varied doing this sort of work. The following week after completing this, I was working on jet engines.

The DPG provided Sarah with the CAD for the parts so she knows the extrusion size needed for the rails and what the end cap parts need to look like.

Peter added: “With this system, she can basically make it as long as she likes and if she has different end caps, she can make different sizes. The main tooling cost is getting the aluminium extrusion for that rail but it’s so universal she can use it in lots of products, not just this.

"I think she went away quite pleased with what we did. I know I really enjoyed working on the project.

“It’s something a little different. It gets you thinking. As a group we really enjoy working with SMEs and it makes life a little more varied doing this sort of work. The following week after completing this, I was working on jet engines. The life of an engineer at the AMRC means you get to do all sorts of projects.”

Sarah has now assembled the AMRC prototypes, carried out some initial testing and market research and is in the process of agreeing with manufacturers the template from which to make the bag tool. This is due to be completed in October and the product is expected to be launched afterwards using Crowdfunding.