Empowering manufacturers with sustainable process tools

09 September 2024The University of Sheffield Advanced Manufacturing Research Centre (AMRC) has collaborated with an industry-led consortium of partners to deliver Project Butterfly - a direct response to the urgent need to decarbonise the manufacturing industry.

Article featured in the latest issue of the AMRC Journal.

The research project drives forward the innovation of digital technologies at the heart of manufacturing processes – with an aim of reducing any environmental impact and accelerating the industry’s journey to net zero. The project explores scalable digital solutions for factory processes to lower CO2 emissions by reducing material consumption and energy use.

Funded by Innovate UK under the Made Smarter innovation challenge, the project consortium comprises a wide array of partners, including the AMRC, BAE Systems, Leonardo, Nissan, Accenture, Intellium, GKN Aerospace, Moy Park and University of Lincoln, UK. The consortium represents a cross-sector interest in developing solutions for decarbonising industry and manufacturing, bringing together research, innovation, demonstration and growth.

As part of the project, the AMRC, a member of the High Value Manufacturing (HVM) Catapult network of research centres, is equipping manufacturers with innovative digital tools to assess and improve process sustainability with ease.

Tace Morgan, senior engineer at the AMRC, said: “In order to meet sustainability goals, we need to make significant changes to UK manufacturing. However, this can seem like an insurmountable task given the ever-changing, fast-paced nature of the manufacturing industry.

“This is what Project Butterfly aims to tackle. It offers manufacturers an easy, yet effective opportunity to take small steps at the grassroots level to improve sustainability in their businesses.”

At the start of the project, the AMRC carried out an extensive literature review around the topic of Resource Efficiency and Energy Efficiency (REEE) in manufacturing, where no consistent approach was found for quantifying and evaluating the REEE of a process at the manufacturing engineer level.

Although some tools and procedures that could aid in assessing REEE were identified, no guidance was found to help engineers walk through the evaluation of a production route and highlight the areas that could be targeted for improvements.

Recognising the lack of a standardised approach for evaluating process sustainability at the manufacturing engineer level, Project Butterfly set out to establish a comprehensive framework that can be used by manufacturing engineers to assess and prioritise areas of their processes for improvement.

This framework centres on two key AMRC tools: the process sustainability calculator and the guidance for process decarbonisation. Tace explains, “The development of these tools is aimed at helping manufacturing engineers to take their first steps towards improving the sustainability of their manufacturing processes, answering the question, ‘where do I begin?’”.

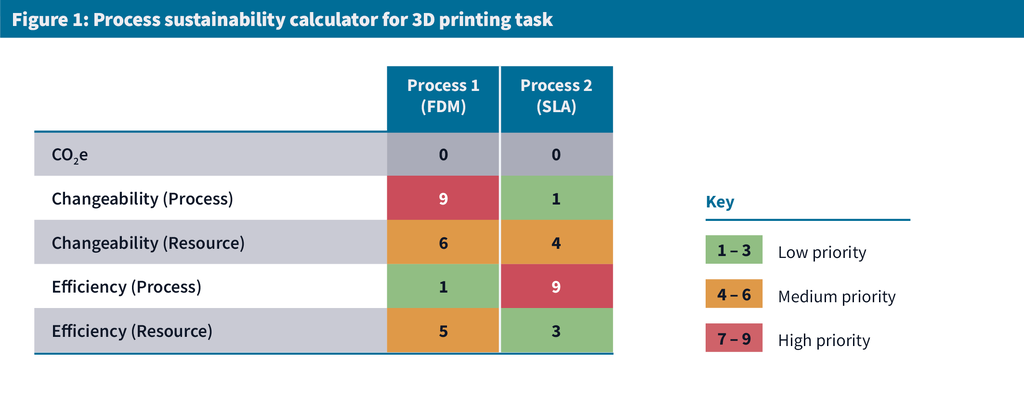

The AMRC’s process sustainability calculator is a tool that will enable manufacturing organisations to identify high-carbon intensity processes qualitatively. The tool helps manufacturers compare several processes (up to five) with the associated resources to identify areas of focus to improve process CO2 equivalent (carbon dioxide equivalent) emissions and prioritise decarbonisation efforts, based on existing sources of data.

The tool can also fill the gap between carbon accounting and life cycle analysis, and will encourage questions about how processes are set up and what can be done to make them more efficient in the short and long-run. It also accounts for the changeability factor, and taking into consideration the ease or difficulty of changing a process, leading to the identification of quick wins in industrial decarbonisation.

The tool is a comprehensive agnostic method for assessing the sustainability of manufacturing processes in any sector. The assessment enables flexibility and allows companies to choose which metrics are a priority to them.

Tace adds: “As sustainability becomes a key driver for businesses, the AMRC aims to provide UK manufacturers with the tools to become more sustainable and make the transition as simple and achievable as possible. This is why Project Butterfly advocates for small changes in manufacturing processes. If more businesses make even the tiniest of improvements in their processes, the overall impact created on the UK's decarbonisation goals will be enormous.”

Building on the calculator, AMRC engineers have created a guidance for process decarbonisation which explains how to use the calculator with ease. It also provides guidance on how to capture and leverage data sources to increase REEE, including using the calculator for further sustainability assessments in an organisation.

How does it work?

AMRC engineers demonstrated the use of the AMRC’s process sustainability calculator via three sample tasks, by evaluating the different manufacturing processes deployed to achieve the tasks to support the aim of Project Butterfly.

The tool along with the guidance developed by the AMRC were used to assess the opportunity for improvements in sustainability for different processes, determining which processes should be given the highest priority

- Sample task 1: 3D printing

The processes chosen are two 3D printing processes – a Fused Deposition Modelling (FDM) process, and a Stereolithography (SLA) process. These processes are frequently used in the AMRC to print prototypes and complex parts used in projects. It was chosen to print the same part on the two 3D printers and collect data from the full process, including post processing.

- Sample task 2: Metal additive manufacturing

AMRC engineers chose two selective laser melting processes used for 3D printing of metal on two different generations of machine. The processes are frequently used at the AMRC to print prototypes and complex parts for use in projects as well as to conduct research on metal 3D printing and metallurgy.

- Sample task 3: Composite material manufacturing

The tool was also demonstrated on two processes often used to conduct valuable research into different composite materials and manufacturing methods. The first process involved the use of an autoclave in a pre-processing step for carbon fibre material laced with a thermoplastic powder that required curing. The second process was a compression moulding cycle carried out on a small press machine.

The clever bit

For every sample, both selected processes were mapped out with the start and end of the processes being defined. The resources used as part of the processes were identified and for each resource that was measured, a value for the CO2 equivalent (CO2e) was retrieved from an existing database. This allowed for the environmental impact of gathering, processing, manufacturing and using a particular resource to be equated to an amount of CO2 in kilograms, enabling it to be compared with one another using a common unit.

The routine use of all sample machines was observed and data was collected from a singular job for both selected processes on each machine using the AMRC’s Factory+ framework and with the help of machine operators. In addition, operators of all of the machines completed a questionnaire on the ability for both processes to be changed and/or adapted.

Process and resource efficiency were calculated using historical data. This, combined with the changeability scores and the data collected for individual processes, was entered into the process sustainability calculator to ascertain a priority score for both processes, which were then analysed to recognise opportunity to improve process sustainability.

Results

Sample task 1:

It was seen from the results of the prioritisation calculator that overall, process two (SLA) scored a higher priority and hence offered the greatest opportunity for improvements in sustainability. This higher score was significantly influenced by the process efficiency and CO2e scores for process two.

For this case study, process efficiency was calculated by analysing the number of failed prints for the month of February 2024. The SLA process had a much higher tendency for the build failing, hence giving it a lower efficiency score and presenting an area where this process can improve. With regards to CO2e, it was discovered that nitrile gloves and IPA wipes were much larger contributors in comparison to model/support material and energy usage, resulting in process two receiving a higher score.

Overall, process one (FDM) scored higher in terms of both process and resource changeability but both processes were reasonably similar in terms of their ability to change meaning this did not have a big sway on the final scores.

Sample task 2:

Overall, the prioritisation calculator results revealed that process two scored a higher priority and hence offered the greatest opportunity for improvements in sustainability. However, both processes scored very similarly due to them being different generations of the same machine.

Both processes scored similarly for most factors except for CO2e and process changeability. The lower score that process two received for process changeability was due to the machine being an older model that is in the process of being phased out, offering a limited ability to update the process. Process two scored higher for CO2e, again due to it being an older model featuring a less

efficient use of resources.

Both processes scored identically for resource changeability and process efficiency, as both used the same types of resources and both had the same tendency to fail. Process two scored higher for resource efficiency due to it using electricity in a less efficient way.

Sample task 3:

It was seen in the prioritisation calculator results (see below) that overall, process one scored a higher priority and hence offers the greatest opportunity for improvements in sustainability. This higher score was mainly caused by process changeability and CO2e. Process two was used to produce a large batch of products whereas process one was used to produce a single product.

For both processes, the raw carbon fibre material was the largest contributor to the overall CO2e. The autoclave was found to use double the amount of electricity per unit of carbon fibre and also featured significant contributions to the CO2e score, because of the bagging consumables required in the process. Both processes scored the same for process efficiency, as both were identified to have a similar tendency to fail. Additionally, both processes scored identically in terms of resource changeability.

For all three samples, it was considered that some of the priority scores may have been exaggerated,as there were only two processes included in the case study hence providing less context for calculating the priority scores.

Find our more about Project Butterfly.