Data-driven manufacturing for Wales

02 March 2022A £3.5 million investment into advanced product verification technologies at AMRC Cymru will deliver digital innovations that connect supply chains, increase productivity, drive sustainability and create high value engineering jobs.

Article featured in issue 14 of the AMRC Journal – out now

Support from the Aerospace Technology Institute (ATI) has allowed the University of Sheffield Advanced Manufacturing Research Centre (AMRC) Cymru to establish a Manufacturing Data Centre of Excellence in Broughton to develop technologies that will allow Welsh manufacturers of all sizes and across all sectors to leverage the data they generate.

“Every piece of equipment we have bought with the grant has been purchased with data in mind,” said Andy Silcox, AMRC Cymru research director. “We want to demonstrate the power of data to improve manufacturing organisations and the kit falls under three categories: data acquisition, data handling and processing, and data visualisation.

“This centre of excellence is investigating how manufacturers can get all the data they need without it being a cost or time burden, to process it efficiently, and then ultimately make data-driven decisions back on the shop floor.”

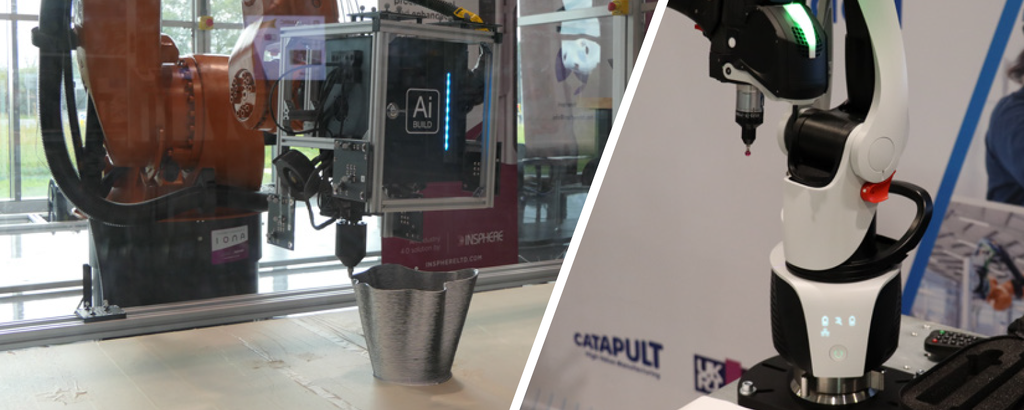

The £3.5 million grant from the ATI programme has been spent on both software and hardware, including: high-accuracy metrology equipment to measure accuracy and update robot paths in real time; projected work zones to show live data; motion tracking haptic gloves; a suite of human behaviour sensors to capture biometric data; and a chroma key room to use with the latest mixed reality headsets.

Andy continued: “You ultimately want to exploit the data you acquire to inform your automated equipment. To do that, you firstly need kit to gather data from the machines; then kit to handle the data, which is the processing equipment; and finally, the kit to effectively utilise that data, to close the loop and improve manufacturing processes.

“We have all that at AMRC Cymru for manufacturers to develop solutions on - from SMEs to OEMs.”

Technologies developed at AMRC Cymru through the centre of excellence will support high-profile projects such as BAE Systems’ Tempest programme and Airbus’ Wing of Tomorrow programme. With Airbus, AMRC Cymru’s first major tenant, the new advanced product verification technologies will help digitalise manufacturing processes.

Sophie Lane, chief relationships officer at the ATI, says the centre is targeting a number of innovations that will make a significant impact on how the UK approaches manufacturing.

She said: “This centre of excellence provides a sandpit environment, independent of any vendor, for industry to develop solutions before they are implemented on the shop floor. Those innovations will lead to a digitally connected supply chain and smart factories that will strengthen the competitiveness of the aerospace sector and wider manufacturing sector in the UK, and lead to the creation of high- value engineering jobs and increased productivity.

The AMRC’s expertise in aerospace assembly and automotive technology is world class. Those skills added to this investment into advanced product verification technologies will be a vital part of the UK delivering high-quality aerospace products at rate and at competitive cost.

Andy says key to the meaningful use of data is understanding what data is important and then knowing that it is accurate.

He said: “Right now, businesses want to understand where they are in terms of their carbon footprint. It’s all very well saying you need to be carbon neutral, but if you don’t know where you are now how can you ever reduce it to zero?

“Manufacturers need to measure energy consumption at a really granular level to understand what is going on in their facilities. Looking at utility bills can only take you so far, it doesn’t tell you as an engineer what you can do about it. The information you need, for example, is to be told that the CNC machine that is 25-years-old is drawing three times the current of a new machine, so you can make an informed decision on whether to invest in a new one.

“That’s the kind of information we’re trying to get - and you get that through acquiring, processing and utilising accurate data.”

Sophie says that thread of sustainability is important for manufacturers large and small, regardless of the sector in which they work, but especially so in aerospace.

She added: “It strikes at the heart of the ATI mission. Designing, manufacturing and assembling aerospace products with the end goal of sustainable aviation must be the focus of the entire UK supply chain if we are to meet the target of net zero emissions by 2050.”

AMRC Cymru, which opened in 2019 with £20m from Welsh Government, is assessing its own energy usage by working with digital transformation company Getronics. The work will begin by evaluating the building management system before measuring every individual piece of equipment.

“Our work with Getronics will allow us to make data-driven decisions on energy consumption,” said Andy. “But the value of data and the equipment we have bought for the centre of excellence doesn’t end at sustainability; from it we can confidently make proper decisions and real changes to all parts of our organisation.

“That’s exciting for us, but also for our partners and the companies with which we work.”

Article featured in issue 14 of the AMRC Journal – out now