Collaborate, lead and educate - how manufacturing can step up to the net zero challenge

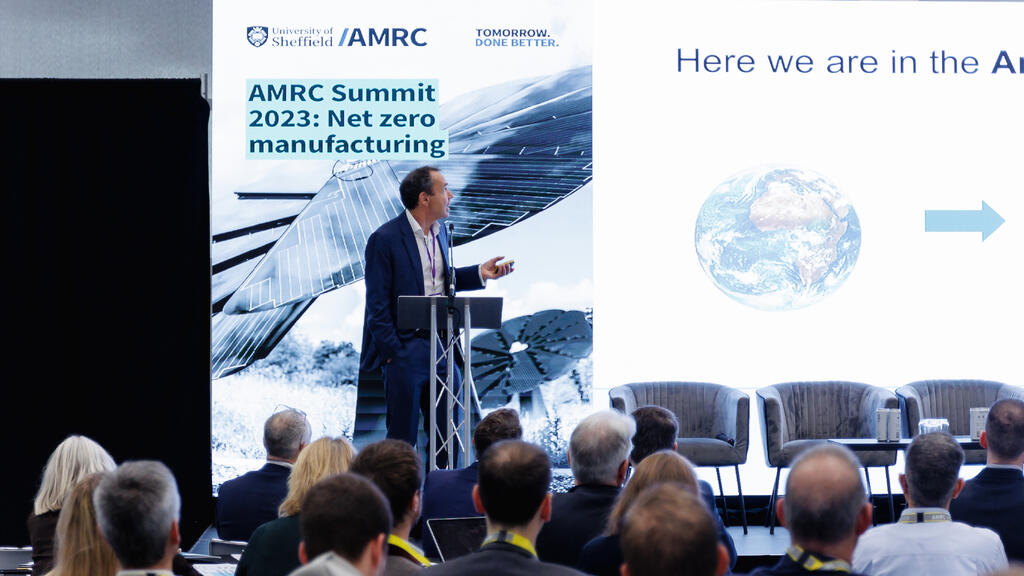

27 November 2023CLIMATE, carbon and sustainability expert Mike Berners-Lee delivered a hard-hitting opening to the AMRC Summit 2023 on net zero manufacturing - setting the direction for a day of deep discussion wrestling with some of the challenges facing industry in the low-carbon transition.

The inaugural AMRC Summit took place at the University of Sheffield Advanced Manufacturing Research Centre (AMRC), inviting more than 100 industrial, academic, political and policy leaders to explore the importance of manufacturing for the UK’s pursuit of net zero and wider growth aspirations.

It was opened by AMRC chief executive officer Steve Foxley with a stark warning from the United Nations ahead of COP 28: ‘We are staring down the barrel of a three degree temperature rise’.

Foxley said the manufacturing industry has ‘all of the key ingredients’ to help secure a long-term plan and told delegates:

“It is time for industry to take a leadership role. There is a gap and it is time for manufacturing to step into that.”

“What’s critical about now, is that now is the moment where unless we make that transition, we are going to be in a great deal of trouble. We have to raise the game - massively,” he told AMRC Summit delegates.

“There is something called a cascading tipping point after which it doesn’t matter what humans do because the temperature has made a step change.

“Antarctic sea ice is 11 per cent less than the previous record. That’s a massive change and if we are not worried about that, we should be. The average ocean temperature is a massive quarter of a degree or so above the previous record. What about the average land temperature? That is a ginormous 0.5 degrees higher since 1940.

“If we are crossing some kind of tipping point, this might be the kind of data we would see.

“What I’m saying to you is that if this isn’t worrying us, or creating a sense of urgency, then we’re not thinking about it properly.”

Berners-Lee went on to say there needs to be a reduction in energy demand, and that the net zero pathway is ‘going to absolutely affect every industry and the technologies within it’.

“It means we need to fundamentally change,” he said.

“For manufacturing, there are challenges right across the sector, including the generation of our renewable energy sources, storage, transmission processes and their application. Most of our transport sources also need to be re-worked.

“Every corner of manufacturing needs to be not just more efficient, but fundamentally need to use different energy sources to the ones it’s using today.”

“The responsibility of every organisation is to deal with carbon in a way that is commensurate with the global challenge.”

A series of energised panel discussions followed, which focused on the imperative for the UK economy to drive the low-carbon transition and the critical role of manufacturing; and on the challenges and opportunities for UK manufacturers to lead the technology changes to net zero - both outside and within the factory walls.

The panels featured key speakers like Andy Haldane, the former Bank of England chief economist who now heads up the AMRC’s Industrial Board; Alex Hickson, head of technology at the Aerospace Technology Institute; Sarah Black-Smith from Siemens Digital Industries; Frank Ashton from Chesterfield Special Cylinders; Steve West, director at small business The Pudding Compartment; Brigitte Amoruso, the senior climate change and energy policy specialist from Make UK; and Katherine Bennett, chief executive officer at the High Value Manufacturing (HVM) Catapult.

They were joined by others including Prof Rachael Rothman, academic lead for sustainability at the University of Sheffield and director at the South Yorkshire Sustainability Centre, whose recent work includes the sustainability of foundation industry processes, plastics and packaging; and Dr Russ Hall, chief engineer for net zero at HVM Catapult, whose seized the opportunity to challenge the audience and fellow panel members around their thinking of net zero and manufacturing.

The first panel discussed the green challenge and the growth challenge, agreeing that having a strategy for manufacturers and sticking to it is key, with Alex Hickson saying: “We are very good in the UK at developing and growing strategies. However it is not just about having a strategy, it’s about having an action plan that sits behind it.”

Andy Haldane believes the growth challenge can be solved, along with the green challenge, by investing in manufacturing. He said: “I think there is sometimes a sense that we can’t make that transition too fast. I think that is a complete misnomer. I think we can’t afford not to do it.

“It’s good for growth, for the planet but also good for parts of the country like South Yorkshire that need to make that transition and need that innovation. So it's three fold - good for levelling up, good for growth, good for the planet.”

Brigitte Amoruso told delegates that net zero does bring commercial benefits, and that the UK is ‘on the right track’, with 68 per cent of manufacturers having already made business investments, and a further 32 per cent planning to do so with one in ten businesses not having any plans.

Alex Hickson said leadership was key to delivering on the investments being made and there were ‘tremendous opportunities’ which the aerospace sector can lead on and those benefits would bleed out into other sectors. He said it was important to ensure industry was working together to ‘unleash the potential we know is there’.

The second panel focused discussion on collaboration and connection, the technology and energy mix to support net zero, the competitive race, and what industry can do to help inform policy.

During discussion on a question about understanding emissions associated with data capture and storage, Russ Hall gave a simple but eye-watering stat on emails, saying that for the average email with an attachment that is sent to ten people is 30 grams of carbon which is enough to drive a diesel van 300 metres.

Hall told delegates that sustainability and decarbonisation are a social need that happens to have a technical engineering solution and ‘everyone in this room has a part to play in that solution’.

“Technology is a response to a problem,” he said. “All the technologies we are talking about today are responses to problems and must be used responsibly and in the right way.

“This problem is bigger than us and technology is bigger than us.

“It needs to be used in the right place, in the right way to enable us all to have a better future.”

The final panel looked ahead to where the next target needs to be and building confidence by looking at who has broken the next barrier and how everyone can learn from that.

Steve West, who heads up The Pudding Compartment, an SME bakery, spoke about the innovation work his company had done with the research team at AMRC Cymru and the particular challenges faced by smaller companies in the race to net zero, pointing to how important it is to use the right language that ‘talks’ to SMEs.

“It’s about education really and it’s knowledge. Most people in my sort of role are so busy just making sure they’re paying the bills that they don’t make the time.

“If anyone had said to me we want to help you save 20 per cent on your electricity - I’d have said let’s meet about that today but if they said let’s talk about your targets for 2050 I would have said let’s meet in 2025 or 2026.”

Leadership and skills were also key focus of discussions.

Ava Jones from AESSEAL spoke about the company’s net zero journey and how it is bearing down on emissions, alongside its ‘£29m by 2029’ initiative driven by its managing director to invest £29m in environmental projects. The company has already invested £12m to date.

Steve West, from The Pudding Compartment, said: “My perspective of being an SME is that you will not be in business long if you do not continue to improve.

“All leadership, at whatever level, has to be willing to change and give your team the permission to get it wrong. You have to have that sort of culture.”

On skills Steve Foxley talked about NextGen, a programme run by the AMRC in partnership with local tech companies, to drive productivity into regional manufacturing businesses through digital technology adoption and skills development.

Foxley also pointed to the apprenticeships delivered by University of Sheffield AMRC Training Centre to create a pipeline of talent for industry with the skills they need to grow and thrive.

The tangible takeaways given by the panel included taking time out and putting time aside to get a plan together; reducing demand usage and taking courage back into organisations to break myths; understanding your targets; be open and make things visible; and take time to understand the data.