Subsurface deformation during precision turning of a near-alpha titanium alloy

Precision turning is an energy intensive, yet important machining operation for critical aerostructural titanium alloy parts.

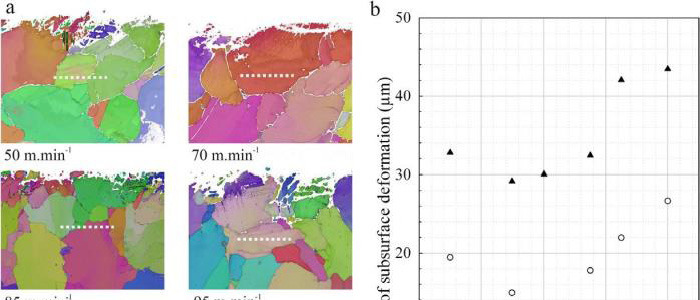

High-resolution electron backscatter diffraction reveals an increase in induced subsurface deformation with increasing surface speed, contradicting observations when applying standard surface integrity techniques.

For this study, near-alpha titanium alloy Timetal®834 (Ti-834) was supplied in the as-forged billet condition from Timet UK. Ti-834 is an advanced aerospace material employed in the compressor sections of gas turbine engines in discs and blades. In order to measure the plastic deformation characteristics during turning, an as-forged condition with coarse alpha grains provides a model microstructure for ease of analysis compared to in-service Ti-834 which has a finer bimodal morphology.

Downloads

- 591.70 kB